Your dryer drum belt is an essential part of the dryer, so when your belt breaks, dryer drum belt replacement is important. Luckily, with the right knowledge, part and equipment, changing your dryer drum belt is a fairly simple task. Read on or watch the related video for any visual guide to changing your dryer drum belt.

Changing Your Dryer Drum Belt

Before you replace the belt be sure to unplug the dryer's cord. To reach the belt you will need to disassemble the appliance. This will require removing or lifting and supporting the very best panel. Depending on the model, you may want to detach the control panel first.

With the very best panel out of the way, you will need to remove one or more front panels. You will often need to disconnect a door switch wire connector before treatment of front panel. Some dryers will have a bulkhead behind the front panel that props up drum. Remove any applicable braces and disconnect any sensor wire connectors, then uninstall the front bulkhead.

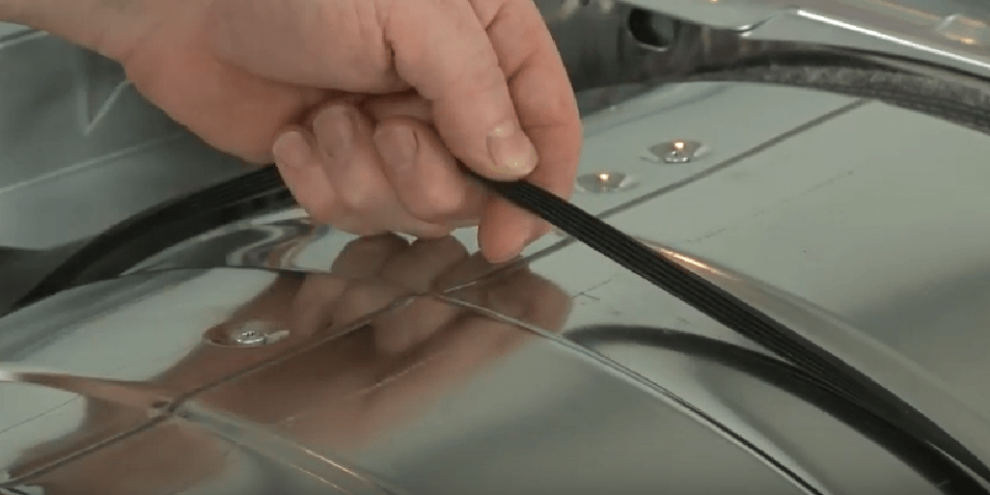

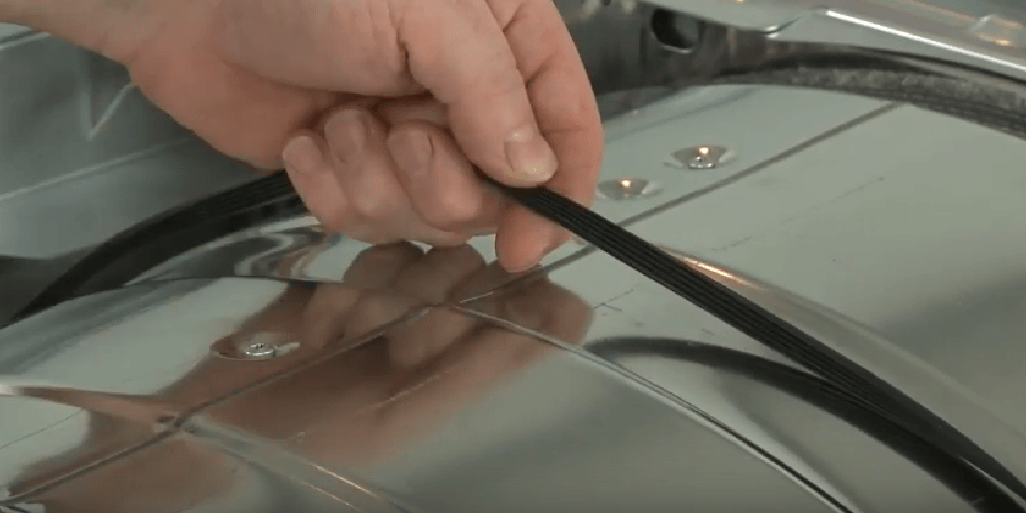

Now reach under the drum and if still intact, detach the old belt from the idler pulley and also the drive pulley then slide it over the front of the drum to remove. Some dryer models have a rear access panel that will make it easier to remove and align the belt around the pulleys. Install the new belt by positioning it around the drum. Most dryers require the groove side of the belt to be facing inward. Loop the belt around the idler pulley and the drive pulley in a zigzag formation. You can rotate the drum to help align the belt.

With the new belt in place, reassemble the dryer by aligning the drum around the front bulkhead, if applicable, then secure with the mounting screws. Reconnect any sensor wires and replace any braces or supports. Reinstall the leading panel, or panels, making sure to reconnect the door switch wire connector if required. Reinstall the top panel and user interface as necessary. With the reassembly complete plug the ability cord back in and your dryer should be ready for use.

What is a Dryer Drum Belt?

The dryer drum belt may be the component that rotates the drum, allowing the heated air to dry the clothes more evenly. The belt circles the entire drum, and is looped on to a drive pulley on the motor, which drives the belt, and around an idler pulley which applies tension towards the belt. If the drum is overloaded, or if a support roller, glide, bearing or pulley fails, the belt can start to slip. Over time, the belt may also fray, and eventually break. Once the belt breaks, you may hear the motor running but the drum will not rotate. On some models, a damaged belt will activate a switch that prevents the motor from running. Drum belts are usually unique to each dryer model. You should enter the full model number of the gas or electric dryer in our website search bar to obtain the specific belt you need.